The cylinders in the drying section are coated with Teflon. There are three different drying systems available in the drying section.

The cylinder drying system dries warp yarns by passing them through steam-heated cylinders. During the drying process, the contact of the yarn with the cylinder causes the surface to dry rapidly. At the same time, the water inside the yarn moves to the surface, carrying the sizing material outward, which forms a film layer on the surface.

The hot air drying system is primarily used for sizing polyester and other filament yarns. In this method, drying starts on the upper surface of the yarn, and as it progresses to the lower layers, the sizing material evaporates, moves to the surface, and forms a film layer.

The radiation drying system removes excess moisture from warp yarns by exposing them to microwave radiation. This system is generally integrated with the other two drying systems for optimal performance.

In our standard productions, the working range is manufactured as 240 cm. Adjustments to the working range can be made based on the specific requests of our clients.

General size options available in our productions include 180 cm, 200 cm, 220 cm, 240 cm, and 280 cm.

Drying Unit features include:

- Teflon-coated and stainless steel drying cylinder.

- Electronic and zonal temperature control enabling independent automatic operation in each section.

- Tension control at the entry and exit points of the drying zone.

- Automatic steam evacuation system.

- Fully stainless steel hood.

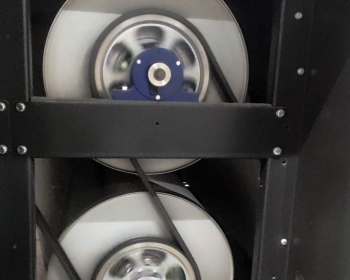

- Radiant fan system providing excellent suction performance.

Other Products