The process involves coating warp yarns with a protective polymeric film by passing them through a viscous liquid with adhesive properties to enhance or preserve their physical and chemical characteristics.

Sizing, a weaving preparation process, is applied to warp yarns to increase their resistance to friction and tension forces during the weaving process. This is achieved by coating the yarn surface with a substance called "size," which minimizes friction and ensures that the yarn"s physical and structural properties remain unaffected.

In our standard productions, the working range is set at 240 cm. Modifications to the working range can be made based on the specific requests of our customers.

General size options available in our production include 180 cm, 200 cm, 220 cm, 240 cm, and 280 cm. Our standard tank is equipped with 2 dipping and 2 squeezing units, but upon special request, configurations such as 4 dipping - 4 squeezing units or other customized designs can also be provided.

Sizing Machine Tank features include:

- An overflow system that ensures minimal sizing consumption.

- An automatic temperature-controlled jacket system providing homogeneous heat distribution at all points inside the tank.

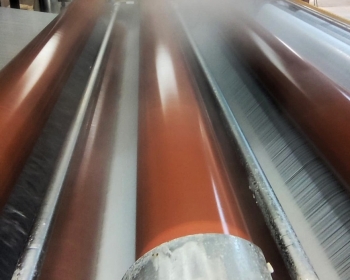

- Rubber-coated dipping and top pressure rollers, and ebonite-coated driven bottom rollers.

- Automatic lifting of pressure rollers during emergency stops or prolonged halts.

- Pneumatic proportional valve-controlled automatic pressure adjustment based on speed.

- Adjustable sizing level inside the tank with a flap system.

- Load-cell-supported yarn tension control at the tank's entry and exit points.

- Control panel for pneumatic pressures and sizing transfer.

- Adjustable pressure settings according to the type and count of yarn.

- Homogeneous pressure effect across the warp width with specially designed pressure rollers.

- Hot water and filtered pre-wetting system to reduce sizing costs.

- Side covers made of stainless steel.

- Side and rear safety guards compliant with occupational safety standards.

Other Products